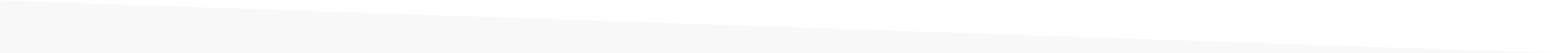

The Role of Grinding Machines in Aerospace Manufacturing

2025/02/10

Introduction

The aerospace industry requires the highest levels of precision and reliability, as even the slightest error in component manufacturing can compromise safety and performance. Grinding machines play a crucial role in ensuring that aerospace parts meet strict tolerances, surface finishes, and durability requirements. With the increasing use of high-performance materials such as titanium, Inconel, and carbon composites, aerospace manufacturers must select the right grinding machines to maintain efficiency and cost-effectiveness.

This article explores the significance of grinding machines in aerospace manufacturing, key factors to consider when selecting one, and the latest technological advancements shaping the industry.

________________________________________

Selecting the Right Grinding Machine for Aerospace Applications

When choosing a grinding machine for aerospace applications, manufacturers need to consider several key factors:

1. Precision and Tolerances

- Aerospace components require extreme precision, often within microns.

- High-precision CNC grinding machines ensure consistent accuracy.

- Machines with automatic feedback systems can adjust in real-time, preventing deviations.

2. Machine Types for Aerospace Manufacturing

Different grinding machines are used based on the type of component and its required precision:

- Cylindrical Grinders – Used for engine shafts, landing gear, and hydraulic components.

- Surface Grinders – Ensure precise surface finishes for structural parts.

- Jig Grinders – Ideal for complex aerospace parts with intricate geometries.

- Tool and Cutter Grinders – Used for maintaining sharp cutting tools essential for aerospace machining.

3. Material Compatibility

Aerospace materials like titanium, Inconel, and high-strength alloys require specific grinding techniques:

- Coolant integration – Prevents excessive heat buildup that could weaken materials.

- Specialized abrasives – Diamond and CBN wheels extend tool life and optimize precision.

- Adaptive grinding systems – Adjust parameters in real-time to maintain accuracy.

________________________________________

Operational Efficiency and Cost-Effectiveness

1. Speed and Accuracy

- CNC grinding machines allow high-speed processing while maintaining precision.

- Multi-axis machines improve productivity by reducing repositioning and manual intervention.

2. Reducing Waste and Improving Sustainability

- Precision grinding minimizes material waste, reducing production costs.

- Efficient grinding reduces tool wear and extends component life.

- Automated waste management systems recycle grinding debris, supporting sustainability efforts.

3. Maintenance and Longevity

- Regular machine calibration ensures long-term performance.

- Predictive maintenance using IoT and AI prevents downtime and costly repairs.

________________________________________

Future Trends in Grinding Technology

The aerospace industry is evolving rapidly, and grinding technology is keeping pace with several cutting-edge innovations:

1. AI and Machine Learning Integration

- Smart grinding systems use AI to analyze wear patterns and adjust parameters automatically.

- Predictive analytics help in preventive maintenance, reducing unexpected downtime.

2. Automation and Robotics

- Fully automated grinding cells reduce the need for manual intervention.

- Robotic-assisted grinding allows for precise, consistent, and high-speed machining.

3. Additive Manufacturing and Grinding Hybrid Systems

- Aerospace is increasingly using 3D-printed metal components, which require post-processing.

- Hybrid systems combine additive manufacturing with grinding to achieve superior surface finishes.

________________________________________

Skill Development and Training for Aerospace Grinding

As grinding machines become more technologically advanced, skilled operators are essential to ensure their optimal performance.

1. Training Programs for Aerospace Grinding

- Many manufacturers offer specialized training courses on CNC grinding operations.

- Hands-on training and simulation-based learning improve efficiency.

2. Certifications and Industry Standards

- Technicians often require certifications to operate aerospace-grade grinding machines.

- Compliance with ISO and AS9100 ensures adherence to aerospace industry regulations.

3. Importance of Skilled Labor in the Age of Automation

- While automation reduces manual effort, skilled operators are still required for programming, maintenance, and troubleshooting.

- Aerospace manufacturers are investing in upskilling their workforce to keep up with new grinding technologies.

________________________________________

Global Market Analysis of Grinding Machines in Aerospace

1. Increasing Demand for Aerospace Grinding Solutions

- The aerospace industry is experiencing rapid growth, increasing the need for precision grinding machines.

- With the rise of space exploration, defense aviation, and commercial air travel, demand for high-precision components is at an all-time high.

2. Growth in Emerging Markets

- Asia-Pacific is seeing increased investment in aerospace manufacturing, particularly in China, India, and Southeast Asia.

- North America and Europe continue to dominate in terms of advanced aerospace production capabilities.

3. Key Players in the Grinding Machine Market

- Several global manufacturers lead in aerospace grinding technology, providing specialized solutions for complex components.

- Companies are focusing on research and development to improve grinding efficiency, reduce costs, and integrate advanced automation.

________________________________________

Conclusion

Grinding machines are essential to aerospace manufacturing, ensuring precision, efficiency, and durability in the production of critical components. Choosing the right machine involves considering material compatibility, precision needs, and technological advancements.

With the industry embracing AI, automation, and hybrid manufacturing processes, grinding machines are becoming more sophisticated and capable of handling even the most demanding aerospace applications. Additionally, the growing need for skilled labor and ongoing market expansion highlight the importance of investing in the latest grinding technology.

Call to Action

At PEIPING, we specialize in high-precision grinding machines tailored for aerospace applications. Our machines ensure superior accuracy, efficiency, and long-term reliability. To learn more about how our grinding solutions can benefit your aerospace manufacturing operations, visit our website or contact our team for a consultation.

Let PEIPING help you achieve precision, productivity, and performance in aerospace manufacturing.