Valve Grinder for Automotive and Marine Applications

2025/04/11

At PEIPING, we understand that engine maintenance isn't just about routine service—it's about delivering precision, reliability, and long-term performance. Whether you're servicing vehicle engines in a repair shop or working with marine engines in ship maintenance, one thing remains constant: the critical role of a tightly sealed valve.

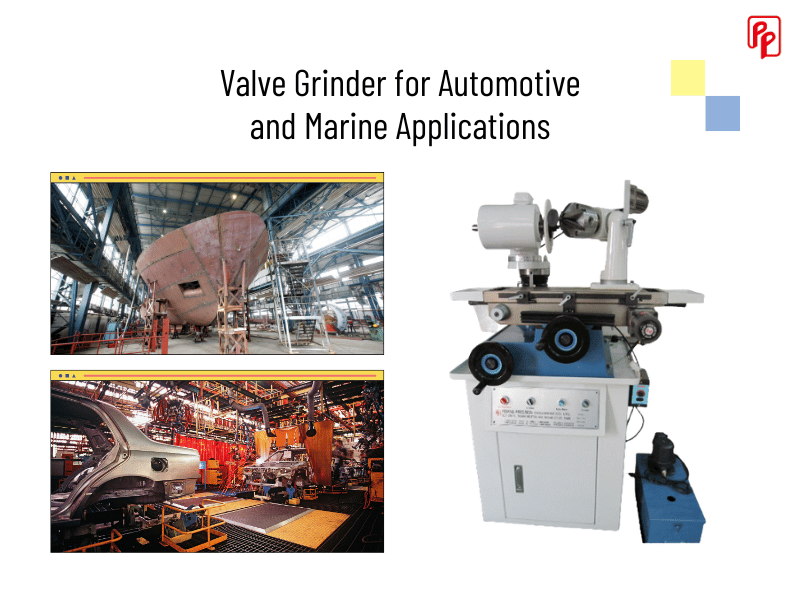

To help engine professionals maintain that level of precision in-house, we offer a semi-automatic valve grinder that is designed for consistent, high-accuracy performance across a range of engine types.

________________________________________

What Is a Valve Grinder and Why Does It Matter?

A valve grinder, also known as a valve seat grinding machine, is used to resurface the contact area between a valve and its seat, restoring the proper sealing needed in the combustion chamber.

Over time, engine valves wear down, become pitted, or carbonized due to intense heat and pressure—especially in marine environments or high-load vehicle engines. Without proper grinding, sealing surfaces degrade, resulting in poor compression, increased fuel consumption, and reduced engine performance.

By reshaping the valve seating surface, a valve grinder ensures tight sealing, restored engine power, and optimal fuel efficiency—all without needing to outsource or replace costly parts.

________________________________________

Why In-House Valve Grinding Makes a Difference

For many years, engine shops and maintenance teams have relied on outsourcing valve work. But as demand increases and turnaround time becomes critical, more professionals are choosing to bring the grinding process in-house.

Here's why our customers in both the automotive and marine sectors are making the switch:

- Consistent Quality – Our machine delivers precise, uniform results, regardless of operator experience.

- Shorter Turnaround Times – No more waiting days for valve jobs to return. You control your schedule.

- Cost Reduction – Cut down on outsourcing fees and extend the life of your existing valves.

- Better Engine Performance – A clean, accurate valve seat means better compression, less fuel waste, and fewer complaints.

________________________________________

Key Features Designed for Demanding Work Environments

Our valve grinder is built for real-world workshop conditions—whether that’s a bustling car service center or a coastal shipyard:

- Precision Grinding – Delivers stable, accurate performance for both gasoline and diesel engine valves.

- Multi-Angle Adjustability – Supports common valve angles like 30°, 45°, and 60°, suitable for various engine models.

- Semi-Automatic Operation – Improves efficiency while reducing the margin of error.

- Heavy-Duty Build – Rigid machine structure ensures vibration-free operation, even during high-speed grinding.

- Easy to Learn and Use – The intuitive interface and stable platform make it ideal for both experienced and newer technicians.

________________________________________

Applications Beyond the Workshop Floor

- For automotive professionals, it's ideal for engine rebuilders, cylinder head repair specialists, and performance tuners.

- For marine technicians, it's perfect for maintaining diesel-powered fishing vessels, cargo ships, patrol boats, and more—where a failed valve can mean unexpected downtime on the water.

________________________________________

PEIPING Supports Your Precision Engine Work

We developed this valve grinder with one clear goal: to empower engine professionals with the tools they need to deliver excellent work—consistently and efficiently. Whether you're working in a garage or dockside, our valve grinder is the solution for those who value precision, speed, and control.

Want to learn more? Contact PEIPING today and let us help you upgrade your valve servicing process with a smart, reliable grinding solution made for modern engine maintenance.