In the precise world of machining and metalworking, the condition of the grinding wheel is paramount. As the wheel wears and accumulates material, its performance declines, affecting the efficiency and quality of the machining process. This is where the process of wheel dressing, particularly through the use of diamond dressers, becomes critical. PEIPING Precision Enterprise Co., Ltd., a leader in the industry, emphasizes the significance of this tool in maintaining the optimal condition of grinding wheels.

Wheel dressing is a critical maintenance task that restores the grinding wheel to its original state or modifies it for a specific purpose. This process not only cleans the wheel by removing clogged material but also exposes a fresh and sharp abrasive surface. By doing so, it ensures that the grinding wheel provides a consistent and precise cut. The process also helps in maintaining the wheel's shape, thereby guaranteeing the accuracy of the workpiece.

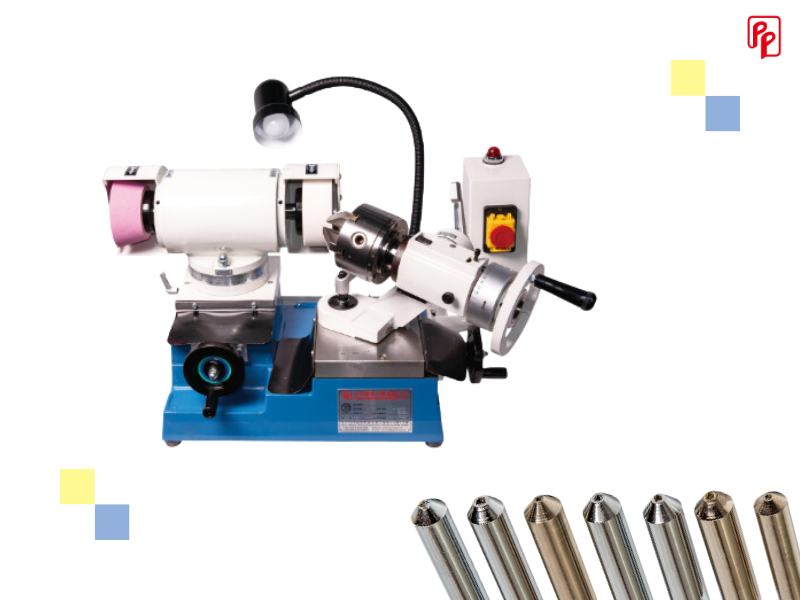

Diamond dressers stand out in the wheel dressing process due to the unparalleled hardness of diamonds, which makes them capable of dressing any abrasive wheel efficiently. These tools are designed to offer precision in reshaping and cleaning the wheel, ensuring that it delivers the best possible grinding performance.

Selecting the right diamond dresser for your grinding wheel is not just a matter of preference but a critical decision that impacts the efficiency, precision, and cost-effectiveness of your grinding operations. Here are the key considerations and steps recommended by PEIPING Precision to ensure you choose the most suitable diamond dresser:

1. Understand the Material of the Grinding Wheel

The composition of the grinding wheel determines its hardness and abrasiveness, which in turn dictates the type of diamond dresser needed. For harder wheels, a dresser with a higher diamond concentration or a tougher diamond type may be necessary to effectively reshape or clean the wheel surface.

2. Define the Desired Finish on the Workpiece

The finish you aim to achieve on your workpiece affects the choice of the diamond dresser. For finer finishes, a dresser with finer diamond grit will be more appropriate, providing a smoother dressing effect on the wheel, which translates to a finer finish on the workpiece.

3. Consider the Complexity of the Grinding Operation

Complex grinding operations that require high precision may benefit from specialized dressers, such as rotary or impregnated dressers, which offer greater control and consistency. Simpler operations might only need a single-point or multi-point dresser.

4. Evaluate the Dresser's Size and Shape

The size and shape of the diamond dresser should be compatible with the grinding wheel and the machine setup. Larger wheels might require dressers with a larger surface area or more diamond points to ensure an even and effective dressing process.

5. Choose Between Natural or Synthetic Diamonds

6. Assess the Dresser's Compatibility with Your Grinding Machine

Ensure the dresser can be securely mounted and is suitable for the speed and power of your grinding machine. The dresser should be able to withstand the forces involved without degrading quickly or causing damage to the wheel or machine.

7. Consult with Experts

Leverage the expertise of PEIPING Precision’s team, who can provide personalized recommendations based on their extensive experience. Their insights can help you select a dresser that complements your specific grinding tasks, materials, and machinery.

8. Trial and Evaluation

If possible, test the selected diamond dresser on a sample workpiece or in a controlled setting to evaluate its performance. This can provide practical insights into whether the dresser meets your requirements for finish, longevity, and efficiency.

Regular and correct wheel dressing with diamond dressers enhances grinding efficiency and the quality of the machined surface. It extends the life of the grinding wheel, reduces cycle times, and decreases the need for wheel replacement, thereby saving on operational costs. Furthermore, proper dressing can prevent damage to the workpiece by ensuring the wheel operates within its designed parameters.

Effective wheel dressing involves maintaining the correct speed and feed rate of the dresser, regular checks to ensure the dresser is in good condition, and adhering to safety protocols. These practices are crucial for achieving the desired outcomes in any grinding operation.

Diamond dressers play an indispensable role in the maintenance of grinding wheels, directly impacting the efficiency, precision, and cost-effectiveness of the machining process. By choosing the right type of diamond dresser and adhering to best practices, manufacturers can significantly improve their grinding operations. PEIPING Precision Enterprise Co., Ltd. remains committed to providing its customers with the knowledge and tools necessary to excel in the competitive world of machining and metalworking.

For further assistance on selecting the right diamond dresser for your needs, do not hesitate to contact PEIPING Precision. Our experts are ready to support your grinding operations with high-quality solutions tailored to your specific requirements.

This site uses cookies to improve your browsing experience. we’ll assume you’re OK to continue. If you want to read more about this, please click Privacy Policy , thank you.