Environmental, Social, and Governance (ESG) principles are becoming integral to manufacturing and metalworking industries, promoting sustainability through responsible operational practices. One significant aspect of ESG focuses on maximizing the life of industrial tools, thereby reducing waste and promoting energy efficiency. Grinders play a pivotal role in this context by ensuring cutting tools like drill bits, end mills and inserts are maintained to the highest standards.

Grinders are essential for the regular maintenance of cutting tools, helping to extend their operational life significantly. By sharpening tools like drill bits and end mills, grinders ensure these instruments perform efficiently and continue to produce clean and precise cuts. Here’s how integrating grinders into maintenance routines can contribute to tool longevity and sustainability:

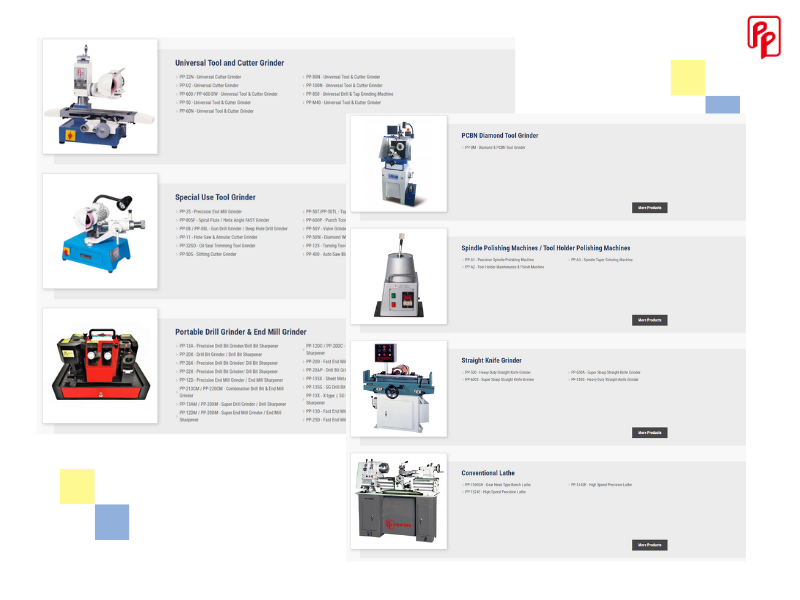

PEIPING Precision, a leader in manufacturing tool and cutter grinders, is at the forefront of supporting industries in their quest to align with ESG goals through efficient tool maintenance. Our machines are designed to cater to a broad range of industrial needs, from small precision tasks to large-scale manufacturing processes.

Industries looking to enhance their ESG compliance and operational efficiency are encouraged to explore the possibilities with PEIPING Precision’s advanced grinders. For further details on how our grinders can help meet your sustainability and operational goals, please reach out to us. We are dedicated to providing insights and support to help you achieve optimal performance and sustainability in your operations.

By prioritizing the maintenance of cutting tools through the use of advanced grinding technology, companies can not only save on operational costs by reducing tool replacement frequency but also contribute to broader environmental sustainability goals. PEIPING Precision remains committed to innovation and sustainability, helping businesses enhance their ESG performance through better tool management practices.

For more information and to learn how our products can become part of your sustainability solution, visit PEIPING Precision or contact our customer service team directly. We look forward to assisting you in advancing your operational and environmental objectives.

This site uses cookies to improve your browsing experience. we’ll assume you’re OK to continue. If you want to read more about this, please click Privacy Policy , thank you.