In the precision-driven world of fabrication, the reliability of welding equipment is paramount. Among the various types of welding machines, the electric welding machine, or welder, plays a pivotal role. This machine facilitates the joining of materials, usually metals or thermoplastics, by causing coalescence. This is typically done by melting the workpieces and adding a filler material to form a pool of molten material that cools to become a strong joint.

Electric welding machines utilize either an electric arc or resistance heating to generate the heat required to melt the material. The most common types include:

Electric welding machines are used across various sectors:

Each of these applications demands high precision and reliability, making the maintenance of welding equipment critically important.

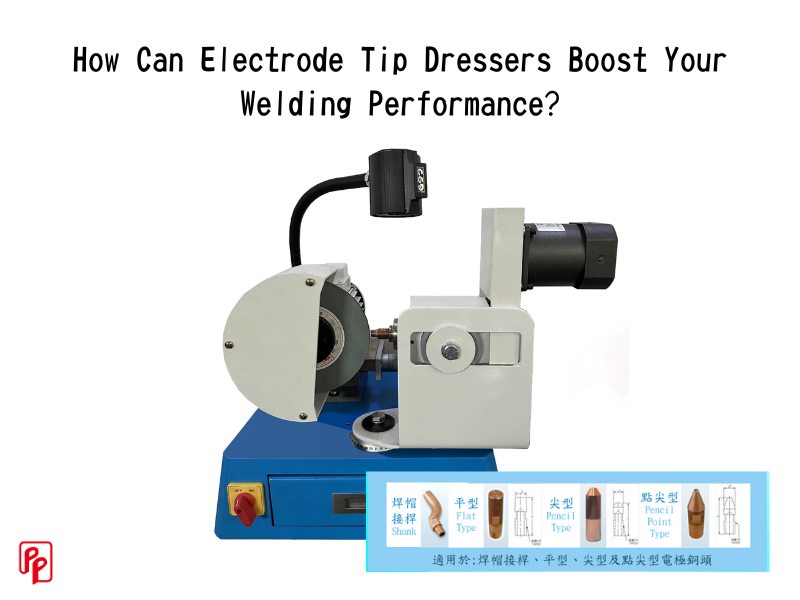

Electrode tips in welding machines, particularly in resistance welding, suffer from wear and tear due to the high thermal and electrical stress they undergo. This wear can affect the machine's efficiency and the quality of the weld. Using a specialized electrode tip dresser, like those produced by PEIPING, helps maintain the tip’s shape and conductivity, which are essential for consistent, high-quality welds.

Our electrode tip dressers are designed to optimize the performance of welding machines by:

For manufacturers and operators of welding machines, maintaining equipment with PEIPING’s electrode tip dressers can lead to improved productivity and reduced operational costs. If you’re looking to enhance the longevity and performance of your welding electrodes, contact us today to learn more about our products. Visit our website or reach out to our customer support team to find the perfect solution for your needs.

By investing in the right maintenance tools, you ensure that your welding operations are always running smoothly, with minimal disruption and maximum efficiency. Let PEIPING help you achieve these goals with our state-of-the-art electrode tip dressers.

This site uses cookies to improve your browsing experience. we’ll assume you’re OK to continue. If you want to read more about this, please click Privacy Policy , thank you.